I noticed during the season a few issues that would cause us some down time . There where a couple brittle hoses behind the front cowling .

Taking care of them on site with my hydraulic hose kit purchased through Lawsons a few years back . Had a few issues making my own hoses but have learned a lot recently with Lawsons help and getting only the fittings and directions related to my shop I can whip them up in no time . Notice the dry and cracked casing of the old hose in picture above . You would never no it was there with out removing shields and cowling . Preventing possibly problems before they happen is always a good thing especially when we use this unit for top dressing days . Otherwise it's mowing approaches and collars .

Similar hose on other end was also ready to go . I'm using bio oil in this model . So far so good . Works great and seems to run cooler .

Traction valve has been seeping all summer . A good time to take care of it in the off season . Comes out fairly easy from the under side .

Clean it off well in the parts washer . Removing this end . Shaft will come out from either end . I try not to lose the adjustment on the lock nut .

Came out with little effort.

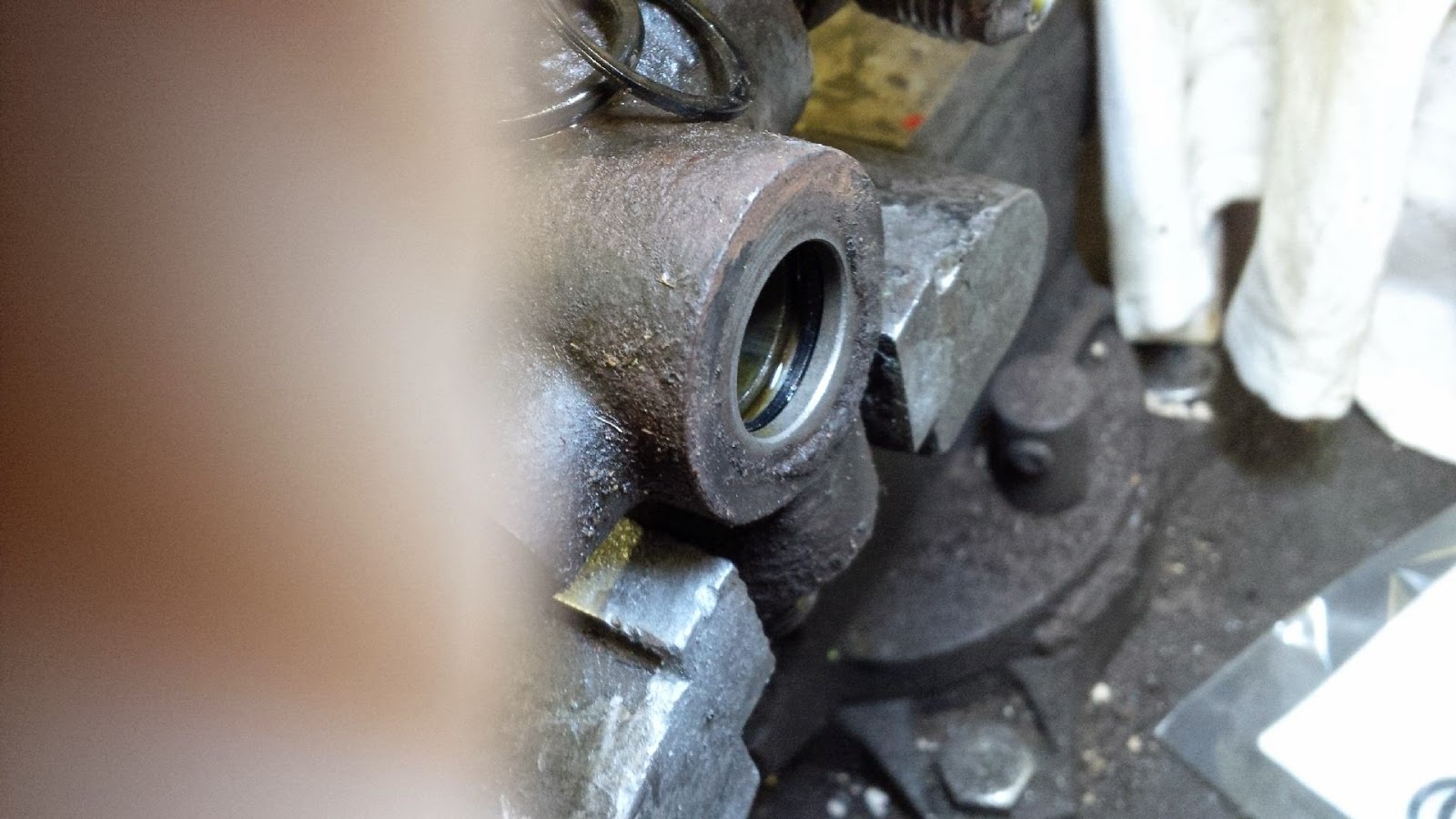

Wasn't hard to see the cause off the leak . Seals where dried out and brittle .

When installing the new seal I put a little hydraulic oil on them. Install the square shaped seal first and then the o-ring behind it after . Both ends are the same .

Lube the shaft with hydraulic oil and slide it back in .

Replace or re-install cir-clip . Feel the inside edge of the clip the sharp edge faces to the outside .

Place shims and spring back on .

Re-install ..It's a tight spot for my chubby hands .

Line everything up and put the 2 mounting bolts in that hold it to the frame . It's a bit trying but can be done . Re-install hydraulic lines (3) and start machine checking for leaks .

Great access to everything with the floor pan off . Valve bank needed an O ring too on one of the lines .

Noticed that the lift arm bushings had a fair amount of play . I cut a groove in the old bushing with a narrow chisel . This is the best way to re-install them. I'll do both ends at the same time . When you have some old gear it will save you a lot of grief in mid mowing season by doing a good tear down on them for service and repair .

.jpg)

No comments:

Post a Comment